Robot dog V1

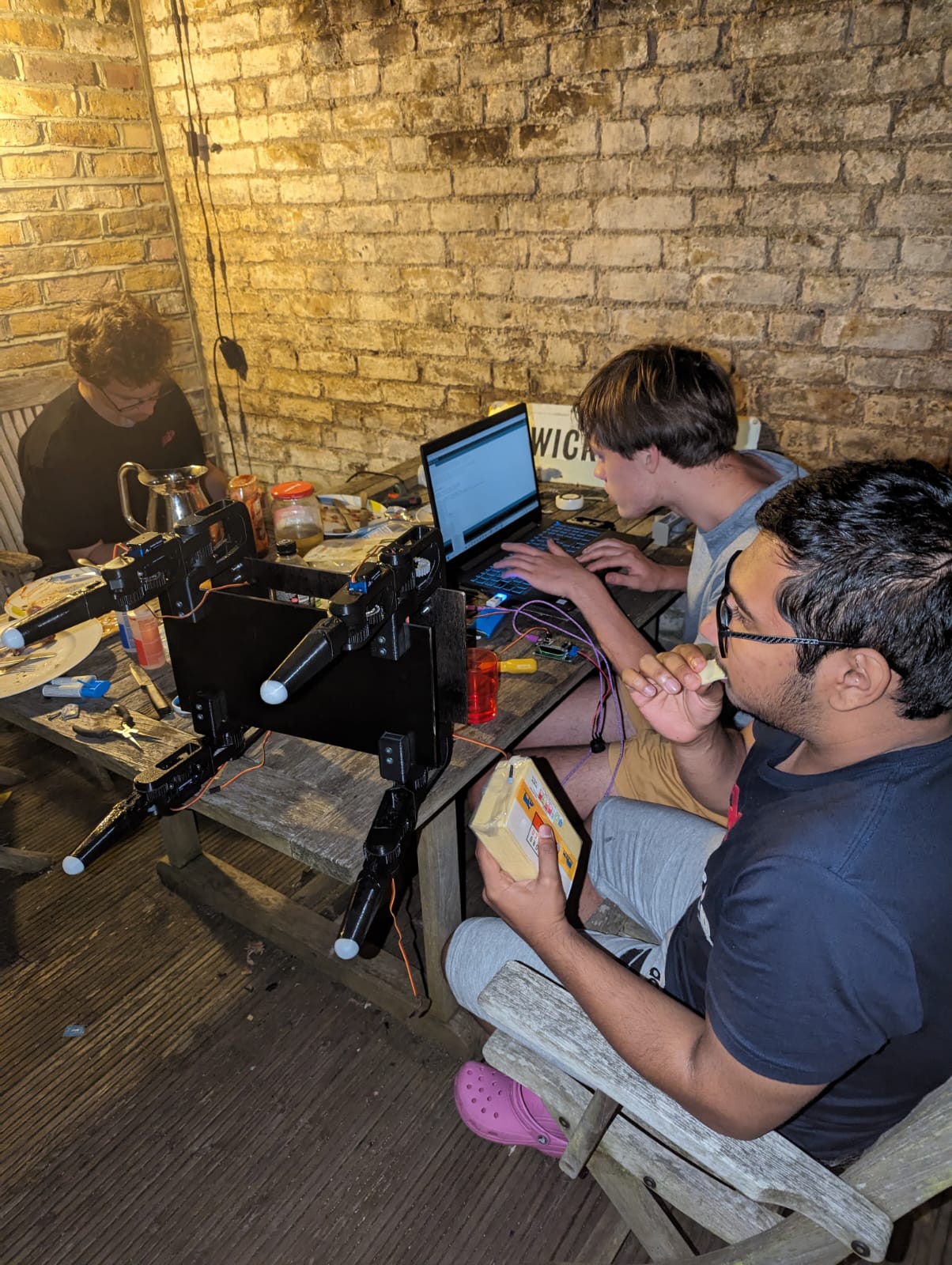

For some reason Kings College London AI team wanted a robot dog. And for some reason they asked me and some friends to build it. So we began.

The first prototype was a work of incredible complexity and pure genius, effortlessly putting Boston Dynamics to shame.

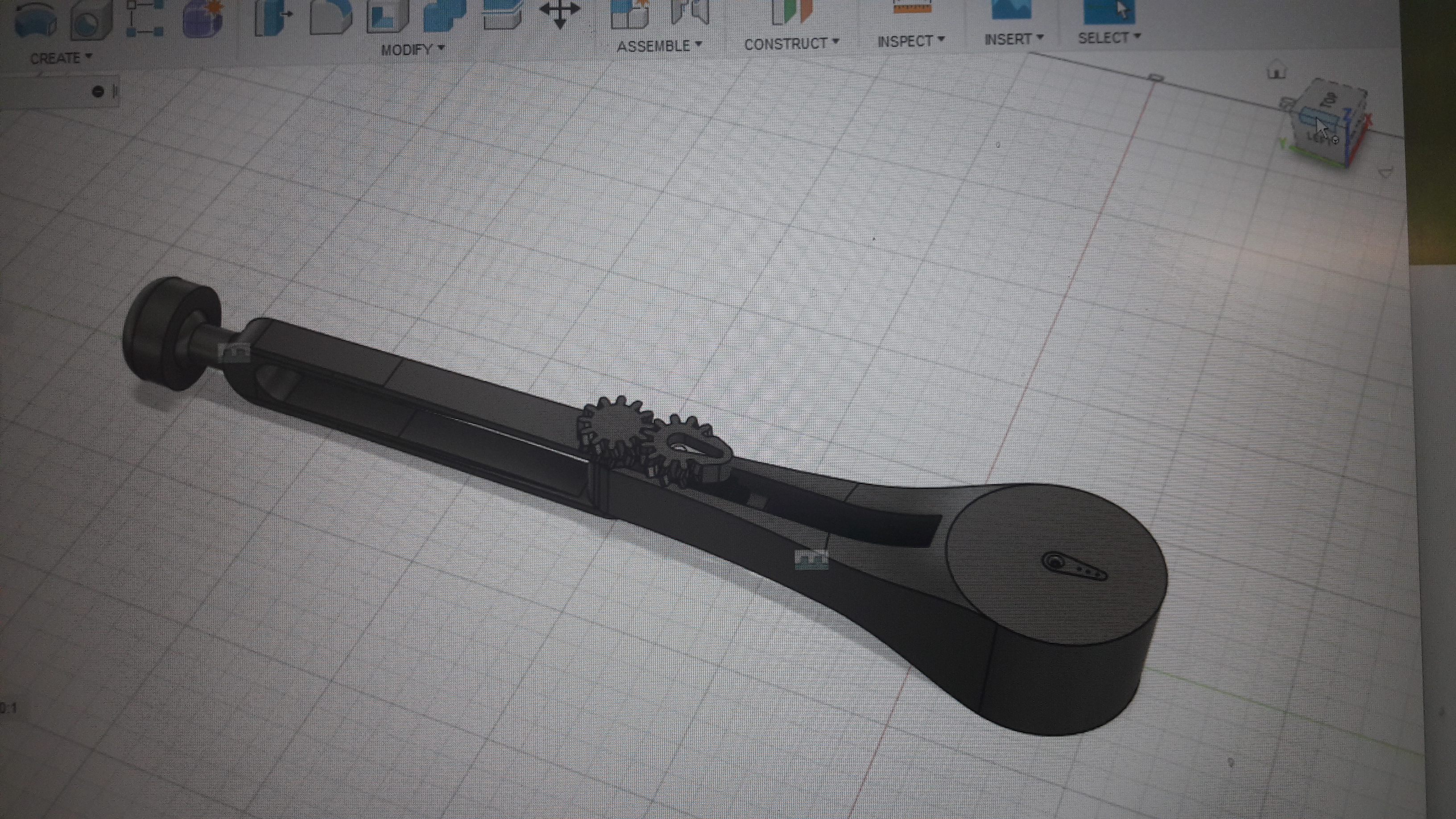

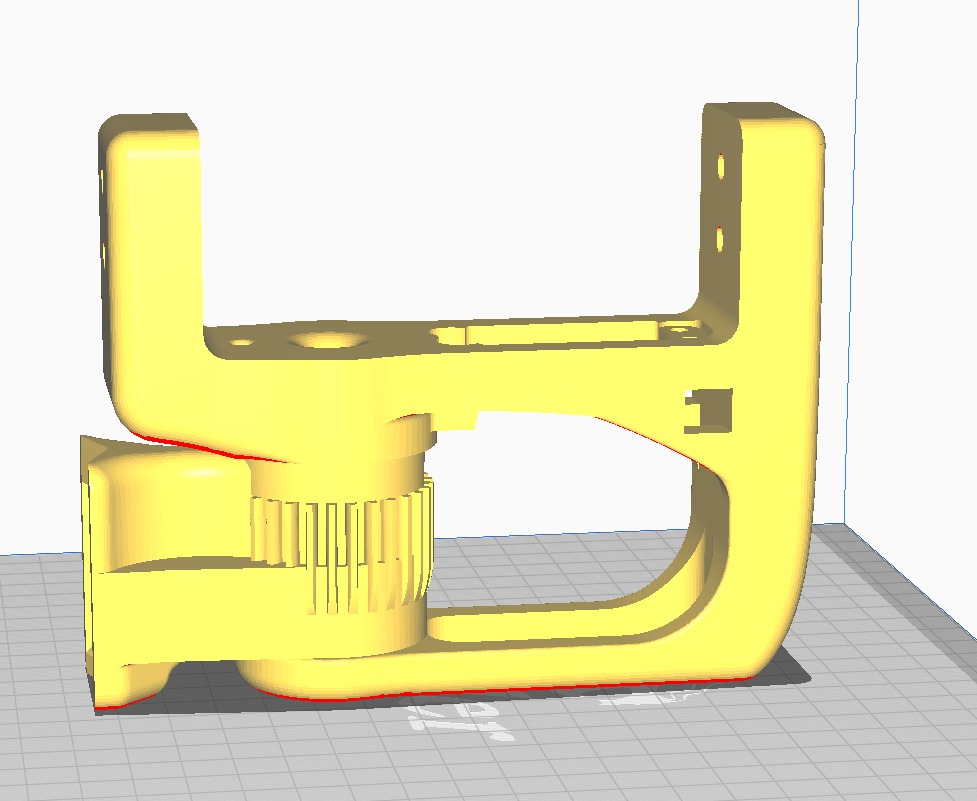

To increase the size and grandeur of our first creation, we designed a larger frame to house the motors. The servo was geared to avoid the "tumour" sticking out of the knee joint.

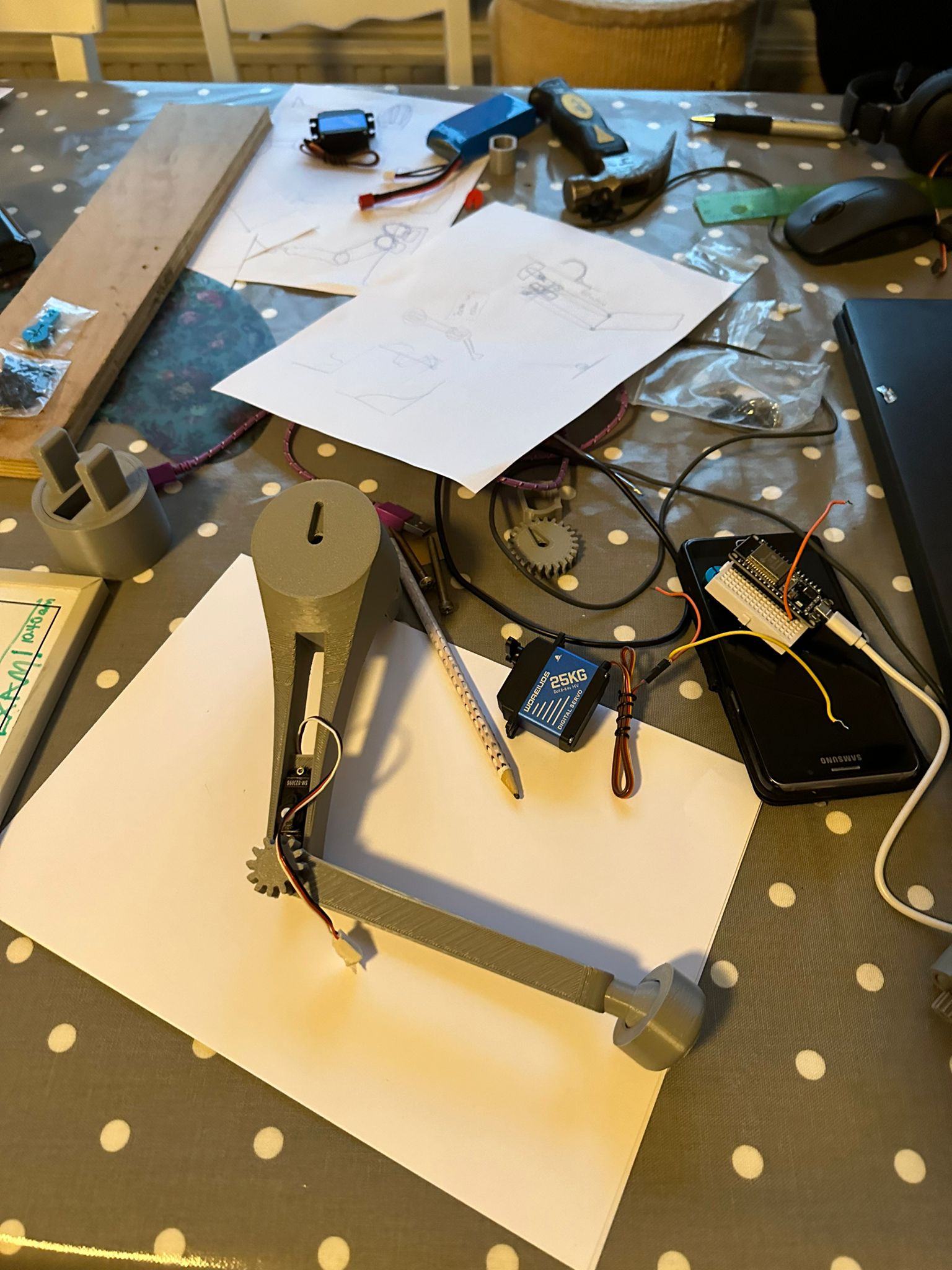

If the goal was a robot worm, we would now be finished. However, you need at least 8 worms to make a dog, so there was still work to do.

We made a leg! But it's terrible. It can barely lift itself, never mind several kilograms of robot. We could've just shortened the limb to like 1/4 of its length and made a tiny cute robot dog that is really cheap, but it was at this point that we realised we were working with someone else's money.

We immediately grabbed the absolute biggest and most expensive servos we could afford with the budget.

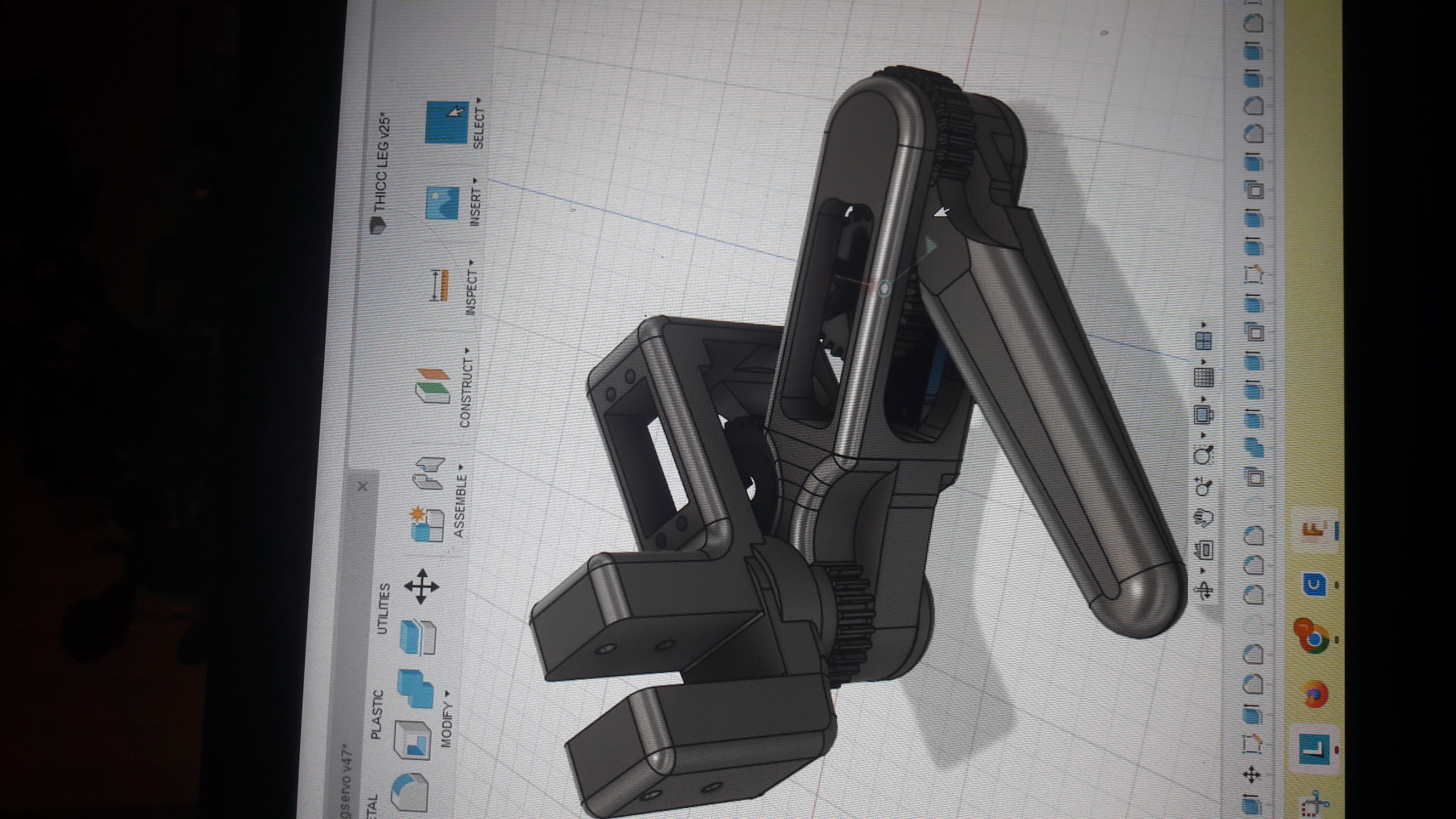

Urgent to flex my fusion 360 skills and excessive attention to detail, I put the servo into CAD. But when I showed it to people, they insisted I had just downloaded it from the internet. It was worth a try I guess.

I actually did design this

It took ages to overcome the impossible design challenges of the bulkier knee joint, but finally it worked, and had an unnecessarily large range of motion for no particular reason. Its best feature was that I was the only one intelligent enough to actually assemble it. And even then it sometimes took multiple attempts. the design uses my patented print-in-place hinges which removes the need for bearings and somehow they don't seem to cause too much friction (I think).

The shoulder joint was much the same as the knee, but much bigger. It took so long to print that I'm sure it kept my sister awake all night at least twice.

But finally the first leg was done! And it worked perfectly. It was even strong enough to lift this jug with 2 litres of water! That would surely be enough to lift the robot, right?

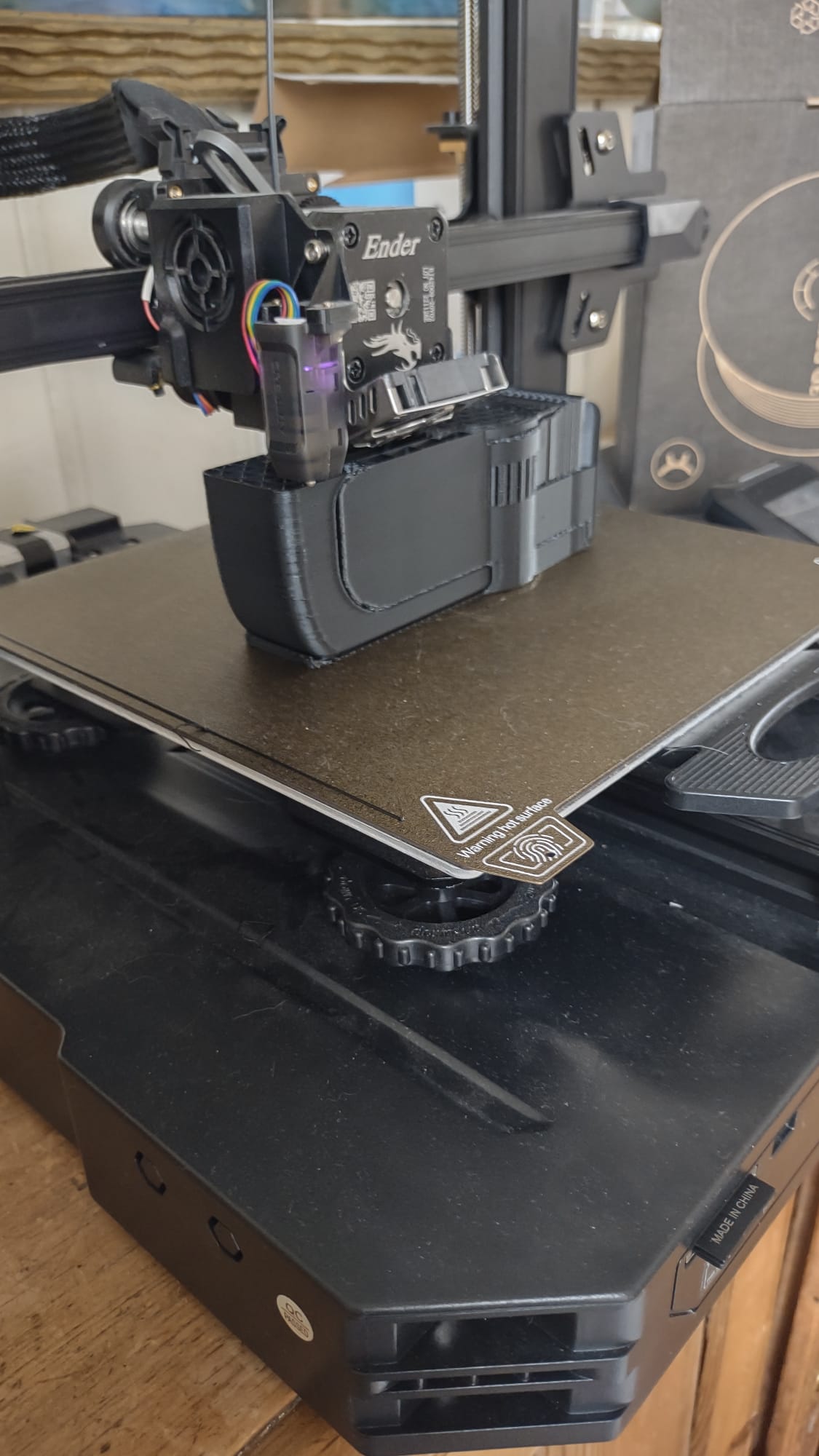

Only time would tell, and a hell of a lot of time it took to print the other 3 legs. Having too many print failures and noise complaints we decided to enlist Georgiy and his ancient Ender 3 into the project.

Unfortunately this was a waste of time, and I inevitably had to print everything myself.

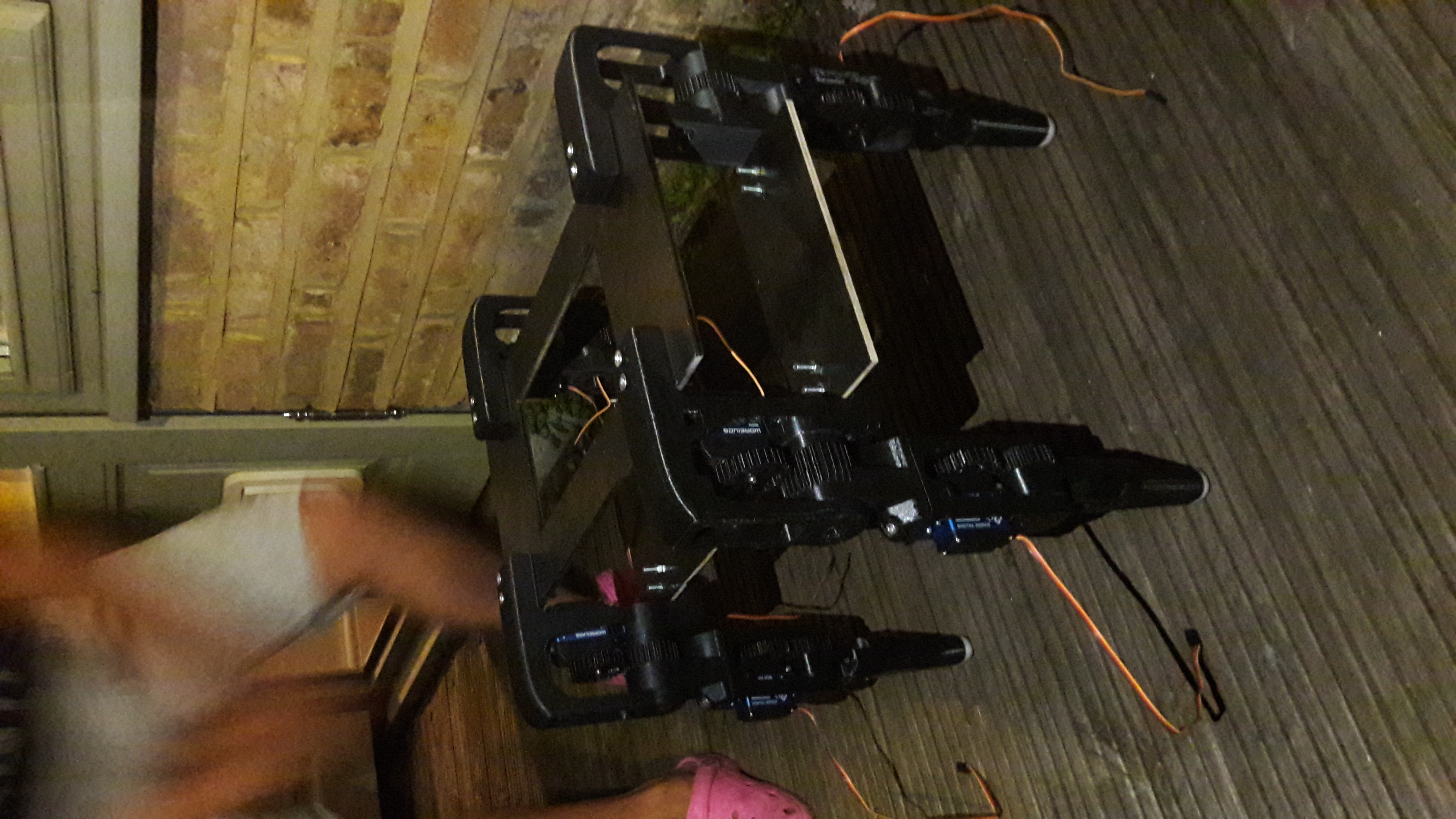

The assembly of the robot was fun as we had to scavenge parts from old or failed bits of the project in a desperate attempt to get it finished on time.

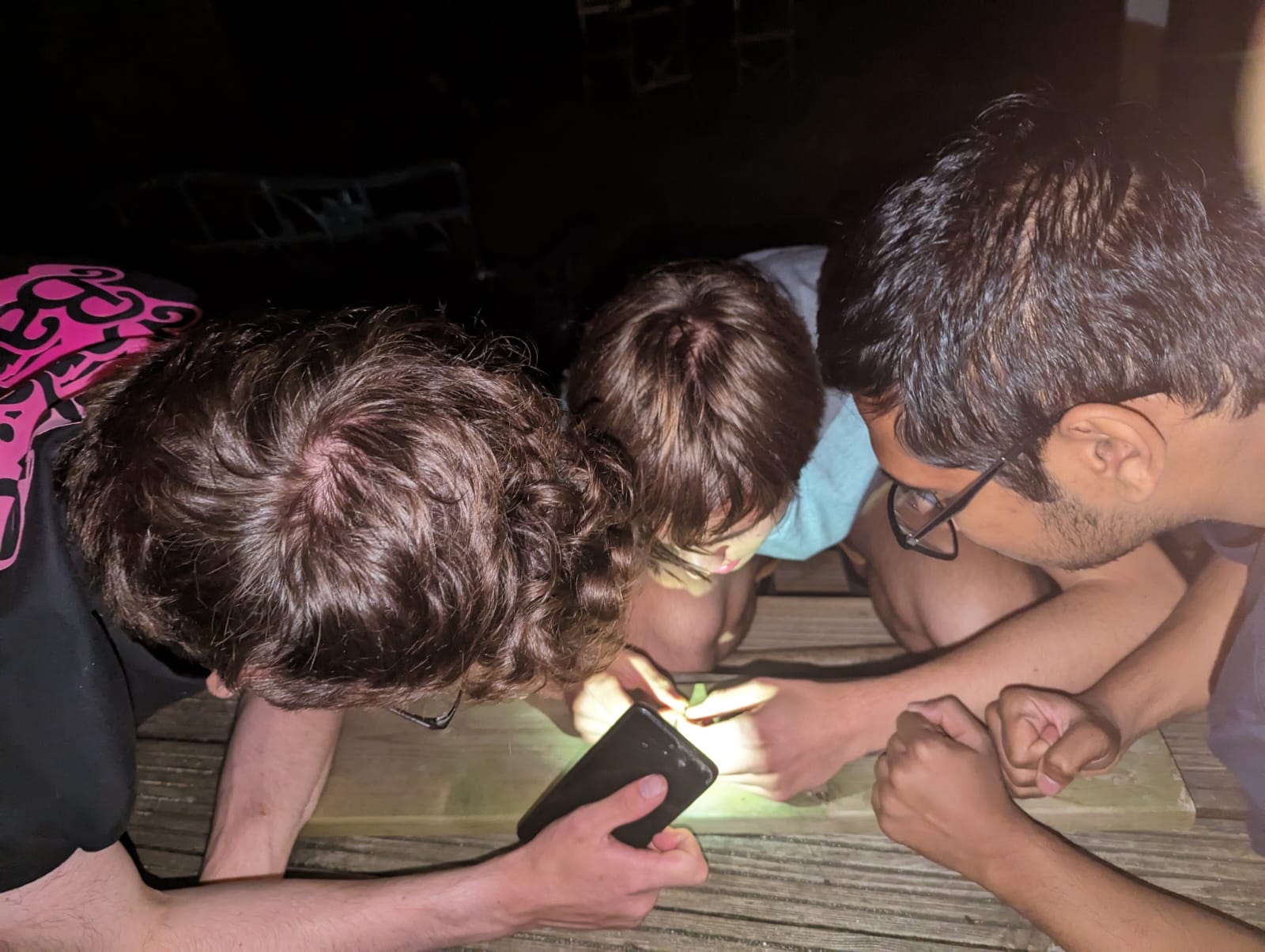

Night fell, and parts started to go wrong without explanation. Suddenly the ESP32 pin 13 randomly died. There was no logical reason for this, because it was connected to a servo signal wire which should only take very low current and be completely isolated from high voltage spikes. Anyway, it had broken, and it needed fixing.

There we go, problem solved.

And now we not only need to find a new ESP32 but also create a new circuit board that doesn't kill it again. The problem is we don't know what keeps killing it. We pondered all the conspiracy theories we could imagine, and decided to fix all of them. This involved begging the aliens for mercy, adding diodes against the back EMF that shouldn't exist, and a 10k resistor to protect every single motor control pin. This means that each servo would have to generate hundreds of volts to be able to break the ESP32.

It can squat a bottle! It was at this point that the King's AI team decided to steal it, take credit for it and break it, only to give it back to us 2 years later. I couldn't be happier. 10 expensive servos and 2 decent LiPo batteries completely for free! The next robot dog will be much smaller, think of a fat bulldog instead of a greyhound that hasn't eaten in a month.